Making a Bennett 966 to visually work - Mon Oct 12 2015 11:25 PM

I've been working on a design to have the Bennett 966 pump I'm restoring to visually work as it did when in service. Here is the progress as of today.

The lights will be activated via the push/pull handle on the side cover. I'll use LED bulbs so the power draw will be minimal. All wiring and porcelain sockets were replaced and wiring is routed through the rigid conduit that was original to the pump.

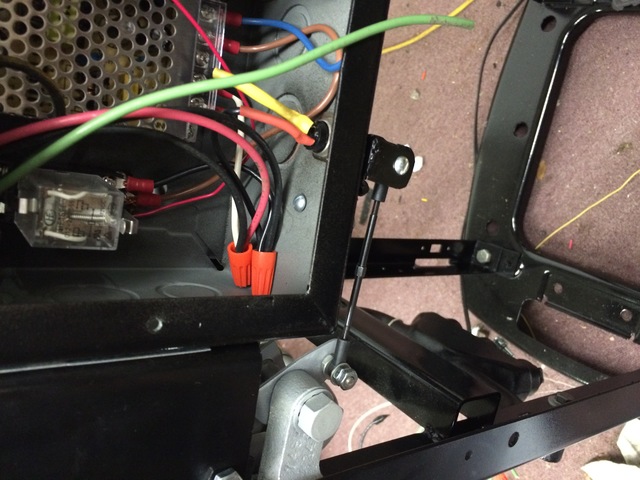

To enable the pump dials to spin when the nozzle handle is depressed I've added a few components. These include a small AC motor, an AC/DC power supply, an Omron 12VDC relay and a small momentary switch.

The lights will be activated via the push/pull handle on the side cover. I'll use LED bulbs so the power draw will be minimal. All wiring and porcelain sockets were replaced and wiring is routed through the rigid conduit that was original to the pump.

To enable the pump dials to spin when the nozzle handle is depressed I've added a few components. These include a small AC motor, an AC/DC power supply, an Omron 12VDC relay and a small momentary switch.

.jpg)